Fascination About Digital Printing

Fascination About Digital Printing

Blog Article

Rumored Buzz on Digital Printing

Table of ContentsSome Ideas on Digital Printing You Need To KnowGetting The Digital Printing To WorkThe 9-Second Trick For Digital PrintingDigital Printing Fundamentals ExplainedSome Of Digital PrintingSome Known Factual Statements About Digital Printing Digital Printing Things To Know Before You Buy

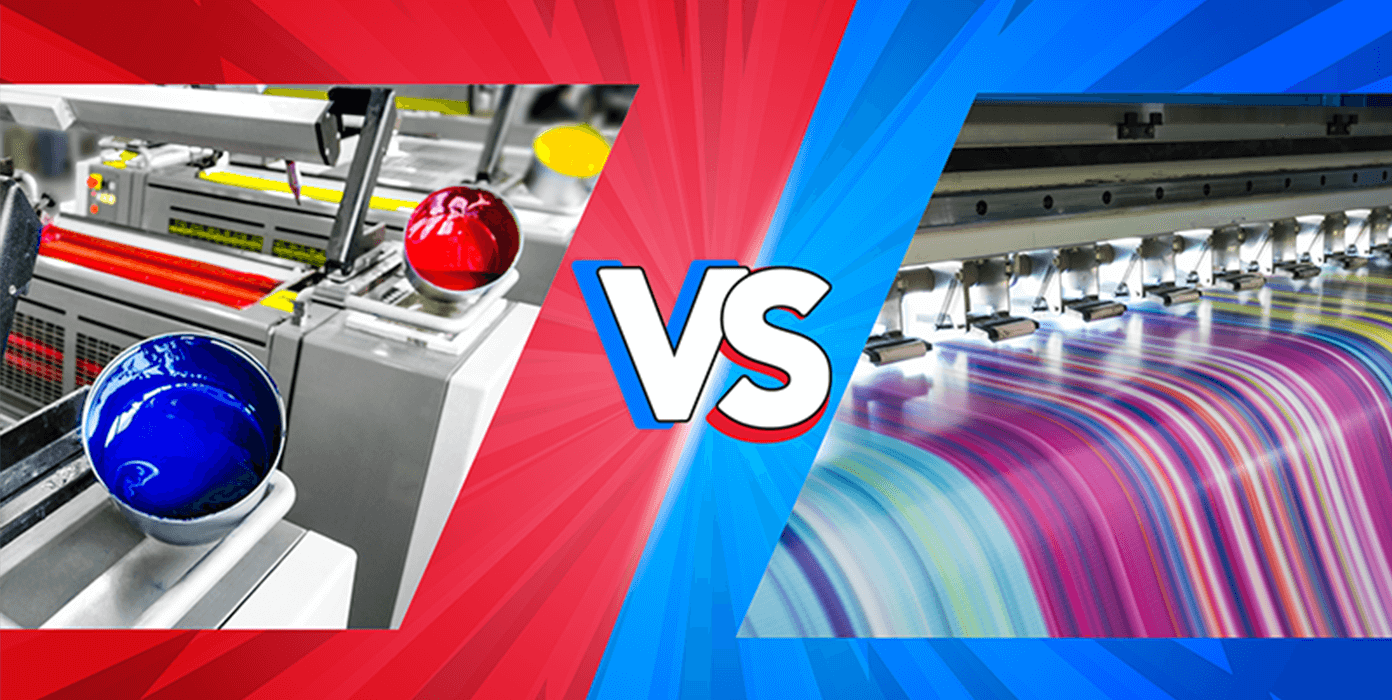

Unlike offset printing (or lithography), electronic printing does not utilize wet ink to transfer pictures using printing plates (Digital Printing). Rather, digital printers make use of an image documents, such as a PDF, to map out the and recreate it. Setup is much faster than balanced out printing, as there are no plates to create and the digital printer handles every little thingToner-based presses use electrophotography, or powder-based pigmented toner that's grabbed by an electric drum and rolled onto the paper or product. Fragments that form an image are then fused to the material using a laser. Toner-based presses were the very first electronic printing method and proceed to continue to be popular today due to their capability to generate high-definition outcomes and print on a large range of materials.

The inkjet printing process includes liquid ink cartridges and nozzles that spray ink out in a mist over an assigned photo or pattern. Inkjet technology has progressed quickly since its innovation and is now made use of in industrial applications such as textile printing, signs, and ceramics, also paper. The current generation of inkjet presses can producing quality that surpasses Toner-based presses and even traditional balanced out presses.

All that's required to develop an electronic print is a high-res picture documents. As soon as that has actually been published, the printer takes care of the remainder, greatly reducing turn-around times for jobs that don't call for big quantities. If your job has a limited deadline, digital printing may be a great option to check out.

Getting The Digital Printing To Work

The brand-new generation of inkjet presses, like Fuji's J Press, are qualified of printing at a top quality degree, shade range, and uniformity that goes beyond also the best standard offset presses. When timing is a worry, electronic printing can be a wonderful alternative. If your project includes a larger amount (i.e.

Digital Printing Things To Know Before You Buy

We've covered the gamut of range printing advantages and benefits.

Digital printing is scalable for reduced and high quantities. For very outlined, visually appealing applications such as prime labels, electronic printing ensures top quality and uniformity, no matter just how big the volume.

All about Digital Printing

It makes use of fewer products and generates much less waste, as there's no need for plates or excess ink (Digital Printing). Furthermore, digital printing enhances the deinkability and recyclability of published materials. Digital printing is versatile for different printing products and thicknesses. Digital printing makes certain superb bond on a variety of substrates. It also supplies high readability, which is important for transferring details in commercial applications.

Digital printing offers added adaptability and creative opportunity. Other printing approaches call for considerable time for the ink to dry, yet electronic printing dries quickly.

Digital printing is a great choice when it concerns following stringent food contact and safety regulations. Some printing can be non-toxic and odorless for food packaging applications. This special feature is crucial for sticking to FDA and business printing standards. Being non-toxic, some digital printing adhere to security top article requirements for youngsters's toys and clothes.

Our advanced equipment enables us to publish applications with resolutions of up to 1,200 dpi and as much as 98 ft. per min. Our electronic printing uses outstanding lightfastness, one-pass opaque white, a vast option of shades, and the peace of mind of being unsmelling, food-safe, and environmentally friendly. Apart from our printing capabilities, Tapecon provides superior solution and know-how.

Not known Facts About Digital Printing

With over 100 years of manufacturing experience, Tapecon functions with product teams to solve challenges, develop items, and improve lives. Discover more regarding our resilient printing and covering solutions.

Plateless digital printing makes possible multi-product, low-volume printing in a limited printing time and more affordable. A minimal printing time enables numerous printing patters, depending on individual needs, creativity or seasons.

Numerous design opportunities with full color and gradation print without the limitation of shades. Full color print is done in one procedure without using plates.

The 9-Second Trick For Digital Printing

Analog printing requires times for shade matching before starting the manufacturing. In electronic printing that time is no required.

Variable information printing and personalized production is also feasible. The needs of the consumers can be now rapidly addressed to, depending on their very own pastimes or seasons. Along with the basic shade prints, the UV inkjet printers permit glossy coating, appearance print, and printed results which includes much more worth to the published products.

Tabulation Litho Lamination (Offset Printing) is a conventional anonymous printing approach and was the most popular choice up until just recently. Litho is the procedure of printing onto paper lining board and after that laminating that onto corrugated paper. Utilizing oil and water, it produces a positive and adverse plate to transfer premium shade graphics onto ideal substrates.

Some Known Details About Digital Printing

The positive plate, with its smooth surface, attracts oil-based inks and wards off water. In comparison, the unfavorable plate, with its rough structure, absorbs water and drives away oil. Rubber rollers are after that used to move the image from the plate to the corrugated surface.

Corrugated paper can in some cases show to be a difficult surface area to print on, yet Litho prints to a separate surface area and is then laminated to it, making it very easy to publish top quality images. It can be exceptionally constant, also for long runs. The a lot more you publish, the less expensive the prices come to be for Litho.

Report this page